What makes Ugur Metal different

Zero-Defect Quality Assurance in Die Casting

At Uğur Metal, quality is not just a final check; it is an integrated process that begins with raw material analysis and continues through every stage of High Pressure Die Casting (HPDC). Operating under the rigorous standards of IATF 16949:2016, we guarantee precision, consistency, and safety for the automotive, lighting, and industrial sectors.

Our Quality Management System (QMS)

We employ a "Total Quality" approach to meet the specific requirements of global OEMs. Our system is built on continuous improvement, utilizing advanced statistical process control (SPC) to monitor production stability in real-time.

- IATF 16949:2024: Certified quality management for the automotive industry.

- ISO 9001:2015: Global standard for quality assurance.

- ISO 14001:2015: Environmental management commitment.

- ISO 45001:2018: Occupational health and safety standards.

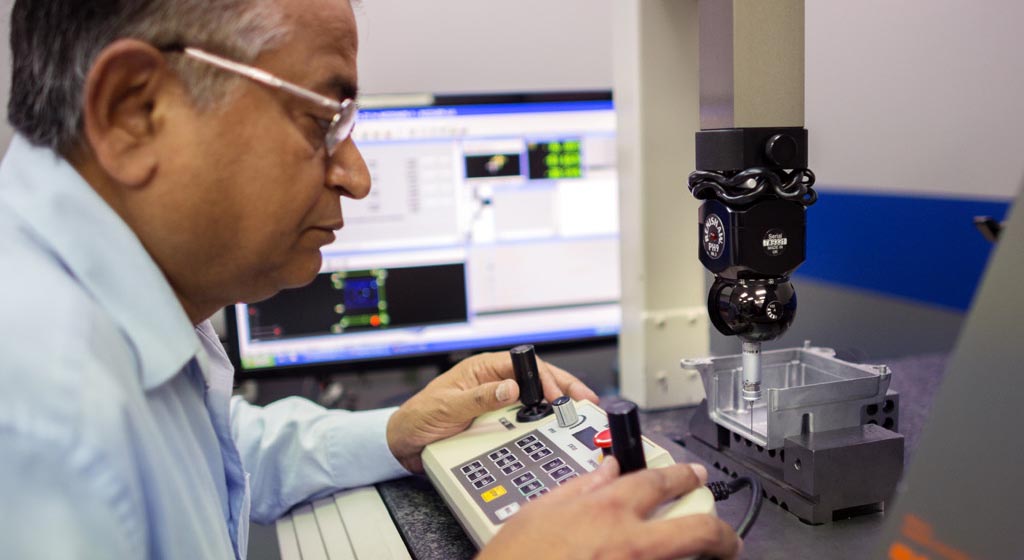

Advanced Metrology & Laboratory Capabilities

Our in-house quality laboratory is equipped with state-of-the-art technology to validate material properties and dimensional accuracy down to the micron level.

1. Dimensional Inspection (CMM)

We use high-precision Coordinate Measuring Machines (CMM) to verify complex geometries and tight tolerances required for engine blocks, transmission housings, and structural parts.

- Equipment: CMM (Coordinate Measuring Machine)

- Capability: 3D scanning and micron-level tolerance verification.

2. Material Analysis (Spectrometer)

Since we produce our own alloys, chemical composition control is critical. Our Optical Emission Spectrometer ensures that every batch of aluminum (Etial 160, EN AC 46100, etc.) meets international standards before casting.

3. Non-Destructive Testing (NDT)

To ensure internal structural integrity and porosity-free casting:

- X-Ray Inspection: Detecting internal voids and gas porosity.

- Leakage Testing: Air-decay leak testing for pressure-tight components like pump housings and valve bodies.

4. Mechanical Testing

- Tensile Strength & Yield Strength Testing

- Hardness Testing (Brinell / Rockwell)

Process Control & Traceability

Every part produced at Uğur Metal is fully traceable. From the melting furnace to the final packaging, we track production data to ensure accountability and rapid response.

CERTIFICATIONS

•ISO 14001:2015 (environment)

•IATF16949:2024

•ISO 45001:2018 (safety)