Ugur Metal Aluminium Die Casting Difference | Innovation

Redefining Die Casting with In-House Recycling & Alloying

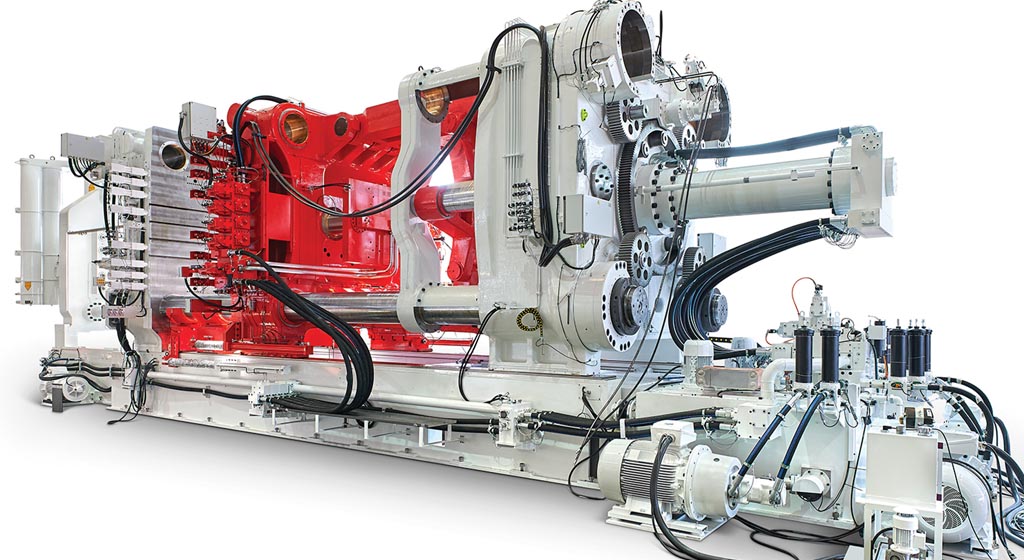

At Uğur Metal, innovation starts before the casting process. Unlike traditional manufacturers, we don't just buy aluminum; we create it. Our integrated production facility features advanced melting and recycling capabilities, allowing us to transform high-quality scrap—such as engine blocks and aluminum wheels—into premium die-casting alloys.

Our Competitive Edge: The "Recycle-Alloy-Cast" Cycle

By managing the entire supply chain from raw material to finished product, we offer our partners unmatched advantages in cost efficiency, sustainability, and quality control.

1. Custom Alloy Production (In-House Smelting)

We have the technology to produce specific aluminum alloys tailored to your project's mechanical requirements. Our in-house metallurgy lab ensures precise chemical composition for:

- EN AC 46100 (AlSi11Cu2(Fe)): High fluidity for complex automotive parts.

- EN AC 47100 (AlSi12Cu1(Fe)): Excellent corrosion resistance.

- EN AC 43400 (AlSi10Mg): High strength for structural components.

- Etial 140 / 160: Standard alloys for versatile applications.

2. Sustainability & Circular Economy

We are committed to the Green Deal. By recycling aluminum scrap, we significantly reduce the carbon footprint of your products compared to using primary aluminum. This makes Uğur Metal the ideal partner for global brands aiming for low-carbon manufacturing.

3. Cost & Supply Security

Importing our own raw materials and producing our own alloys eliminates dependency on external ingot suppliers. This vertical integration protects our customers from market fluctuations and ensures a stable, cost-effective supply chain for high-volume projects.

Conclusion:

Uğur Metal is not just a die casting factory; we are a sustainable material science partner. We turn scrap into value, delivering high-pressure die casting solutions that are greener, stronger, and more competitive.